CNC Conversion

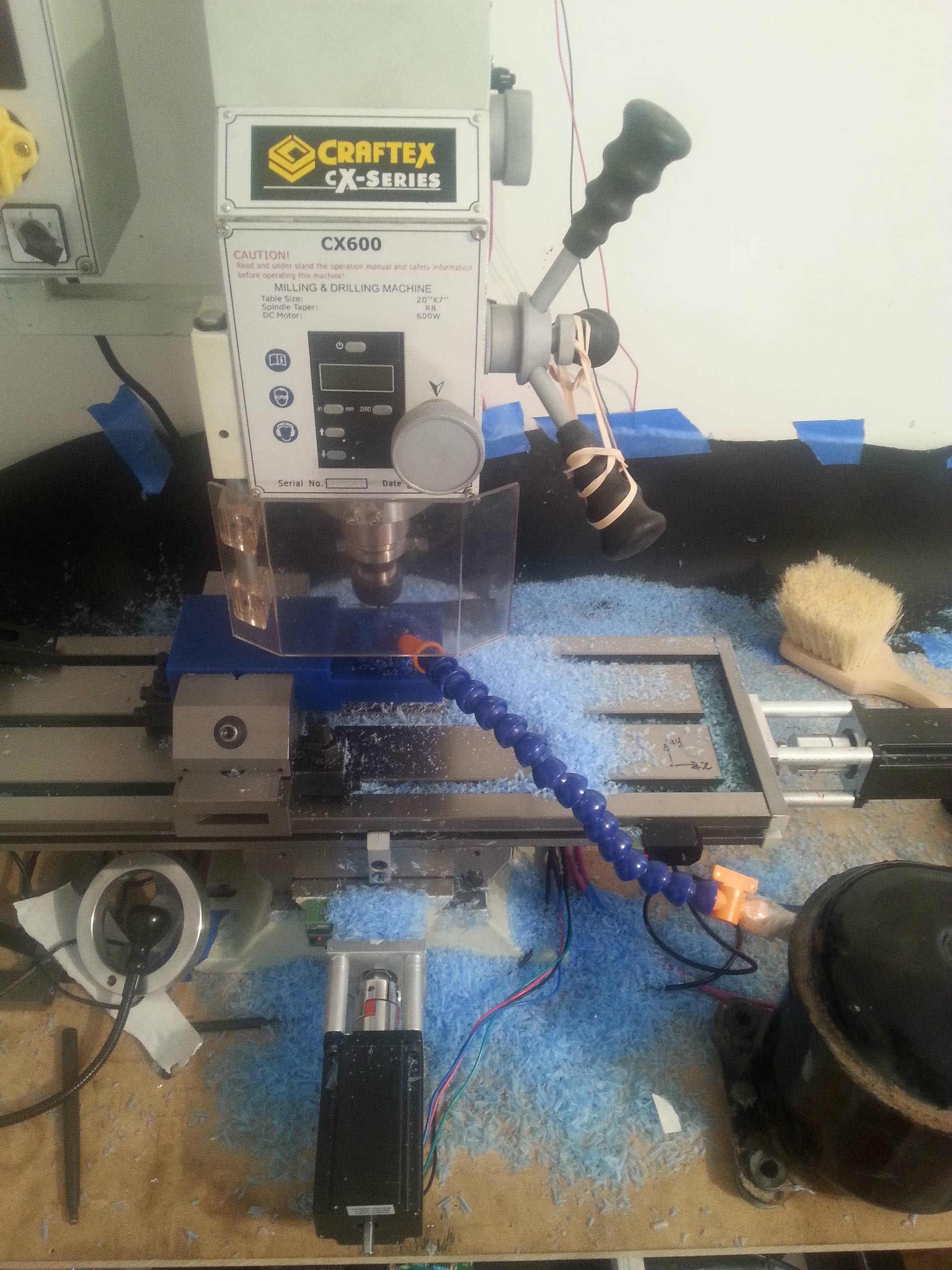

3D printers are very useful and have their place, but for serious parts a CNC is a proven necessity. This project is the conversion of a Craftex CX601 mill into a capable CNC mill.

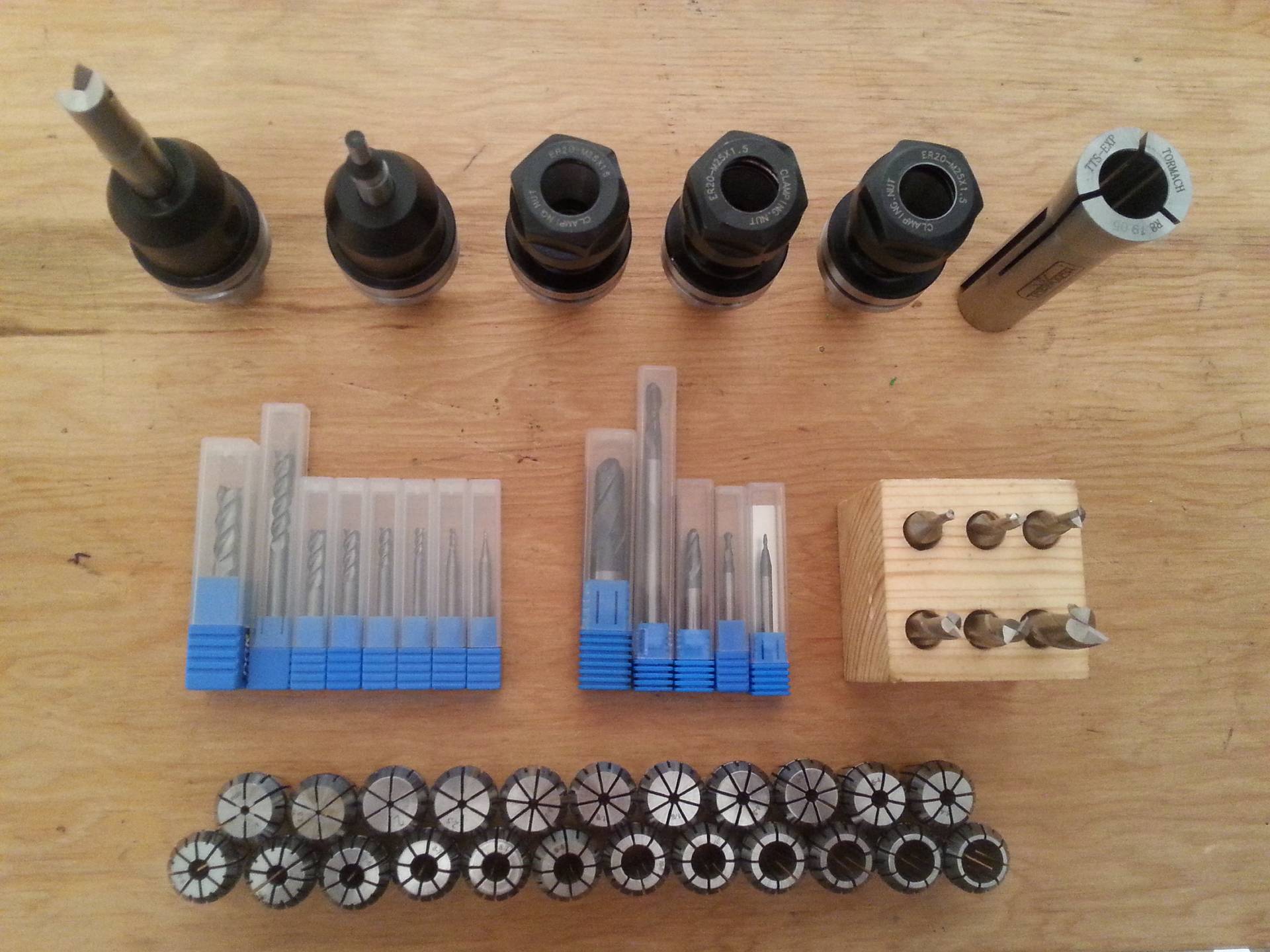

The mill’s spindle is R8, but most of the work will be small, so for convenience a Tormach Tooling System (TTS) adapter and a number of ER20 collects were purchased. The straight shank and positive interface of the TTS allows for a number of permemnatly setup tools with measured offsets to facilitate toolchanges.

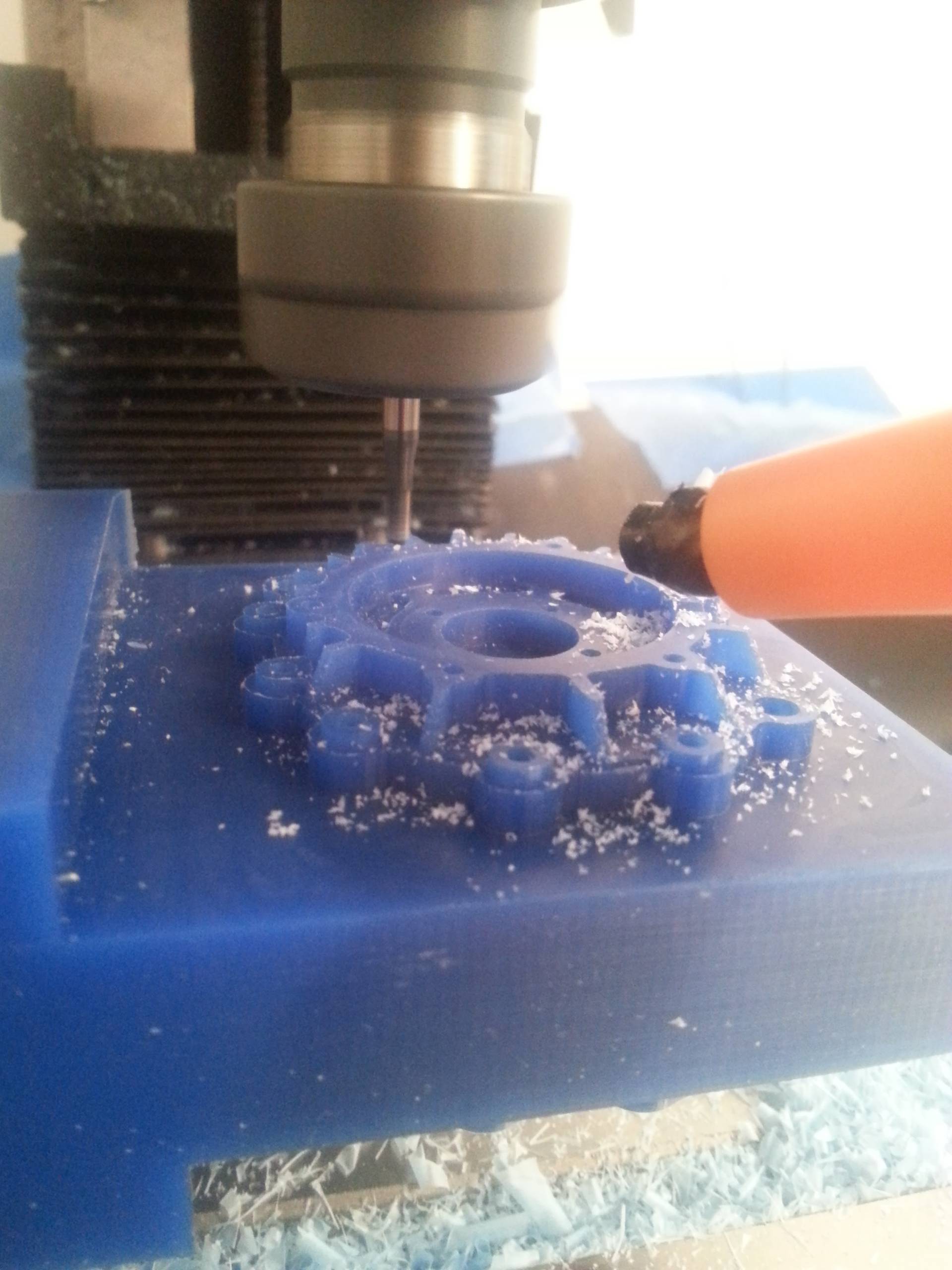

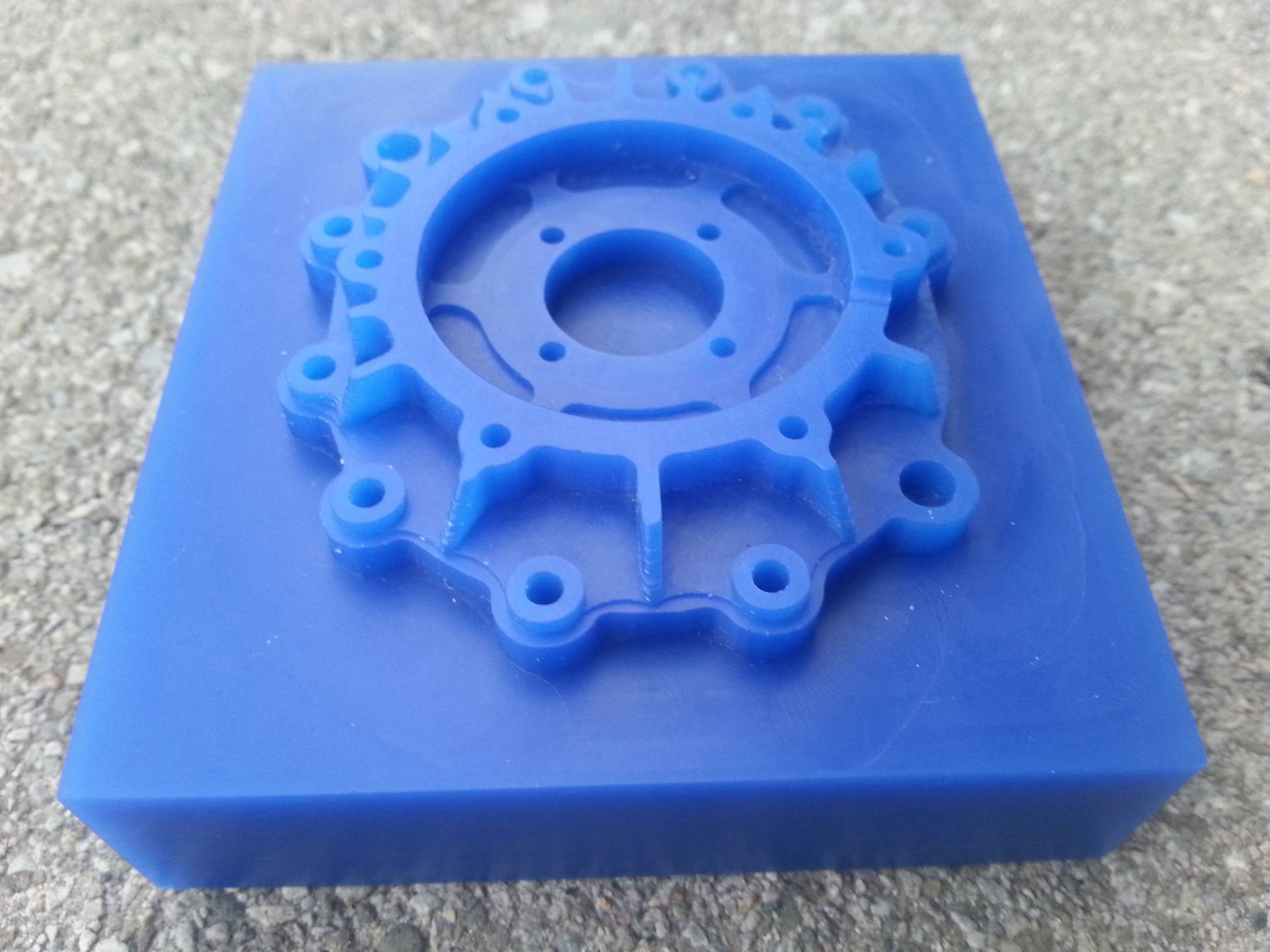

With the basic conversion complete, it was possible to cut a test piece. This is using machining wax, which is relatively (but not completely) forgiving of programming errors and machines easily. A model wankel engine was chosen as the first test piece